We provide high-quality thermal insulation and jacketing works to commercial building projects of various scales. Our core capabilities include but not limited to insulation works using Phenolic foam, PU chemical, K-flex, as well as jacketing works using PVC, Aluminium and GI sheets. These are most commonly performed on chilled water pipes of all section types and chillers such as Trane, Carrier and York.

Please refer to the sample of projects below and our workmanship showcase webpage to see if we can fulfil your insulation needs. Otherwise, you may also contact us with your enquiries here.

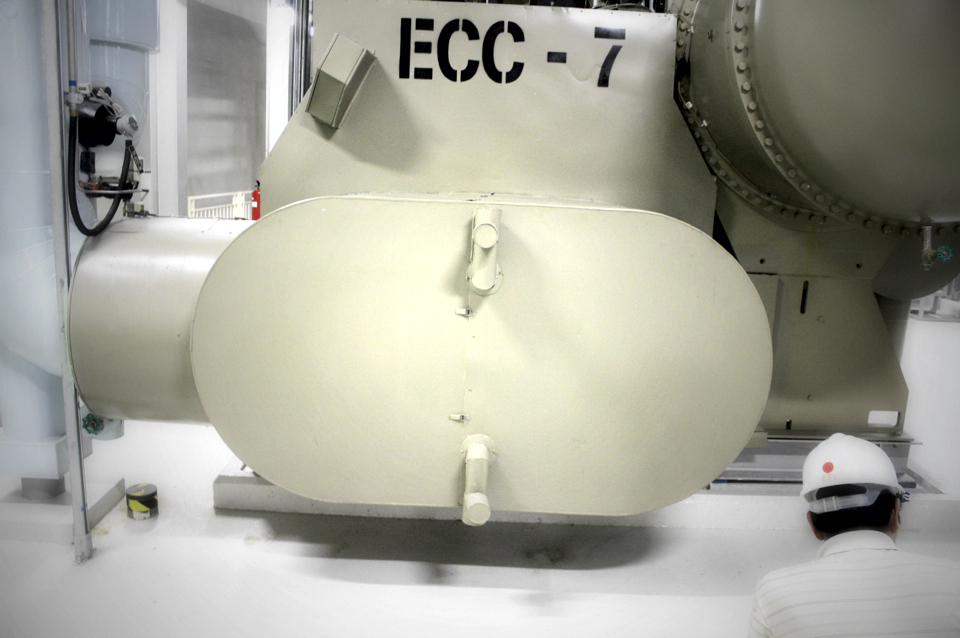

Rolls-Royce opened its new MTU Asia Headquarters in 2015 with the completion of the 26,500 square metres facility at the Tukang Innovation Park. MTU is one of the world's leading manufacturers of large diesel engines and complete propulsion systems. The MTU brand is part of Rolls-Royce's Power Systems business.

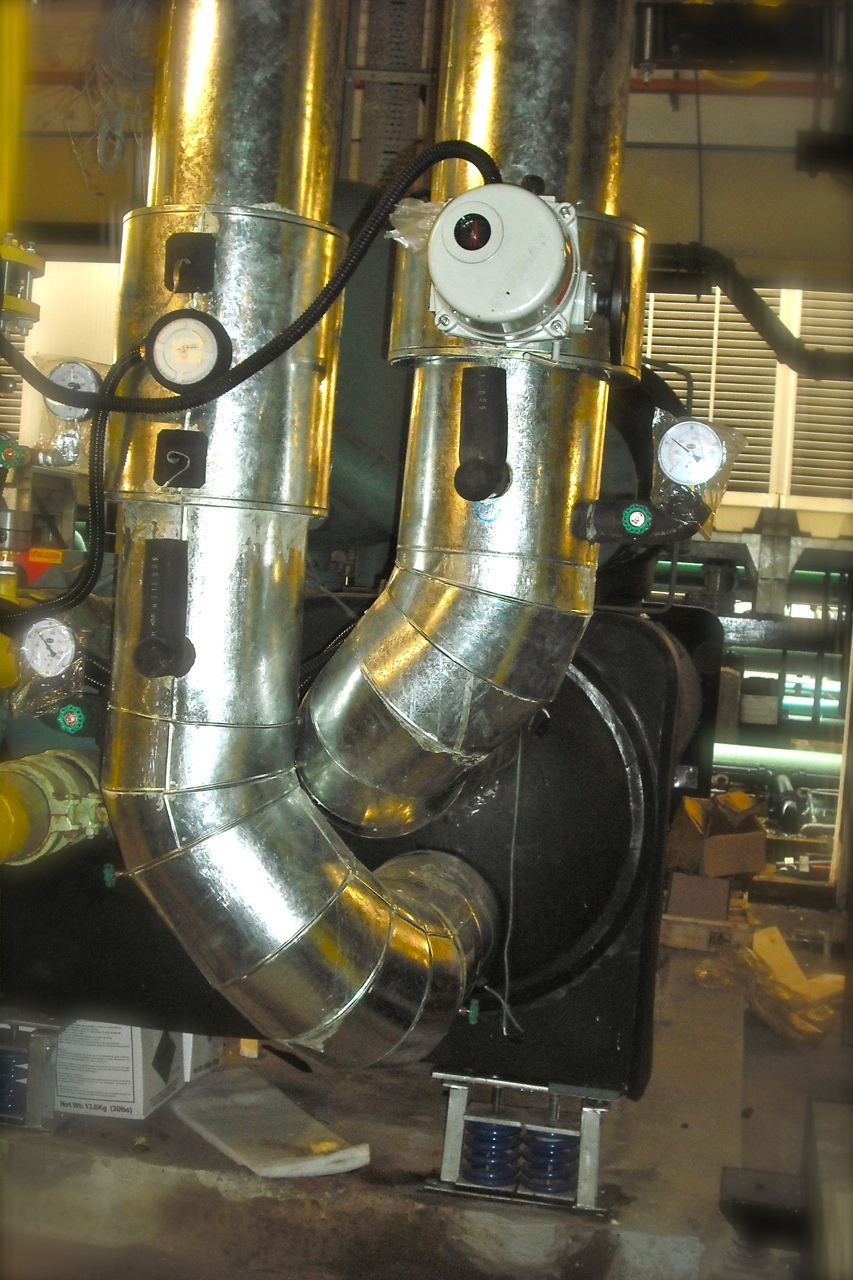

Goodever fitted the facility's one thousand degress hot air pipes with ceramic Isowool and Rockwool insulation. The extensive insulation work is completed with aluminium jacketing.

The fab 10X facility is a 255,000 square foot expansion for Micron current fab 10N manufacturing complex, which will increase its Singapore NAND flash memory fabrication capacity.

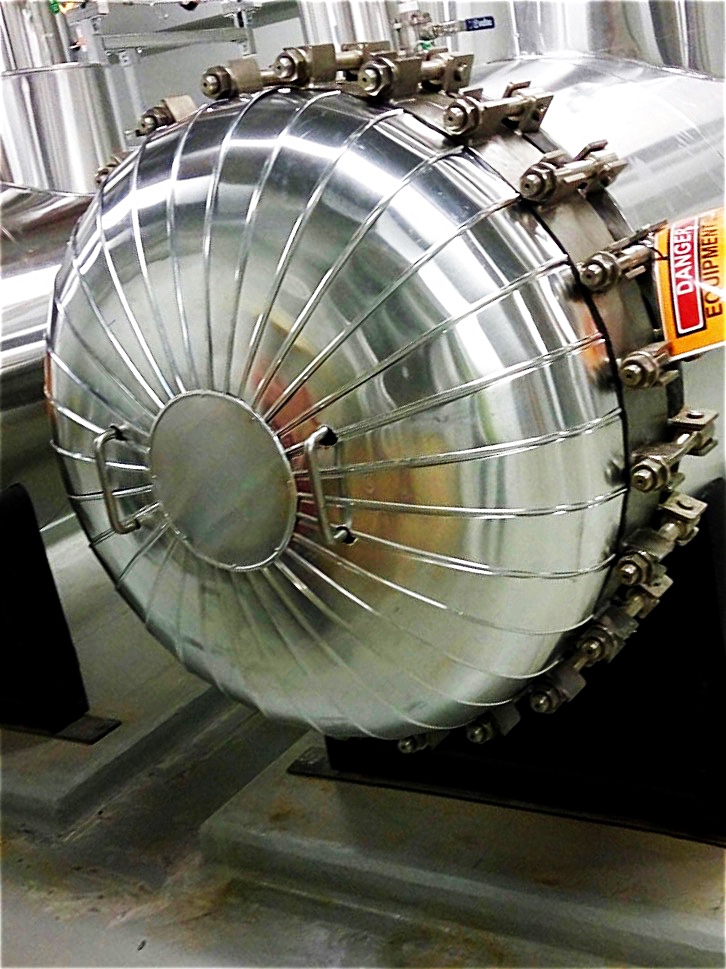

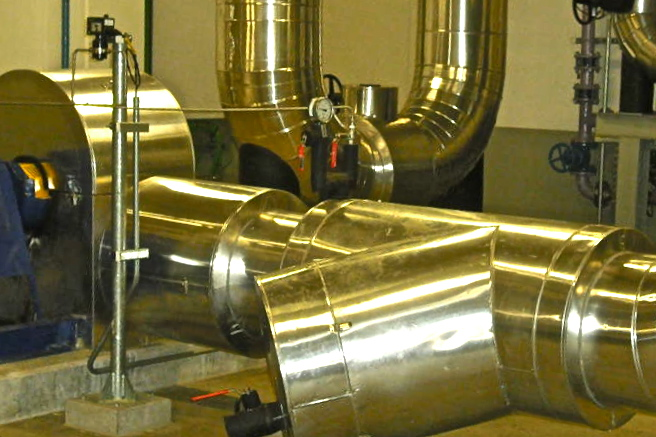

Goodever is proud to be engaged again for this expansion project where we will supply insulation and jacketing works using K-flex and Aluminium for the entire plant. Scope of work includes pumps, filter tanks, air separator tanks and Y-strainer sections, etc.

Filter tanks insulation with K-flex complete with Aluminium jacketing.

Y-strainer sections insulation with K-flex complete with Aluminium jacketing.

Air separator tanks

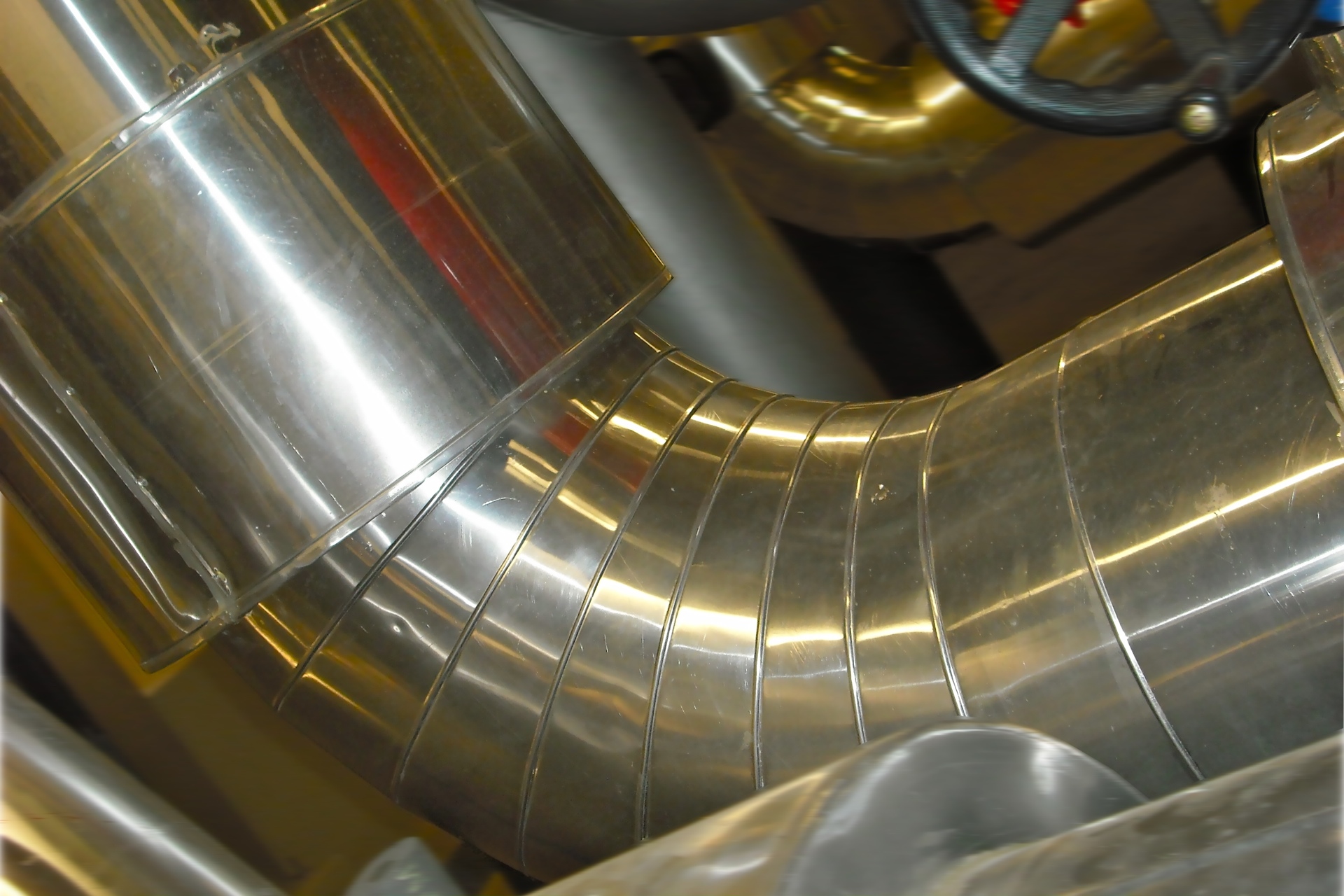

Elbow pipe sections

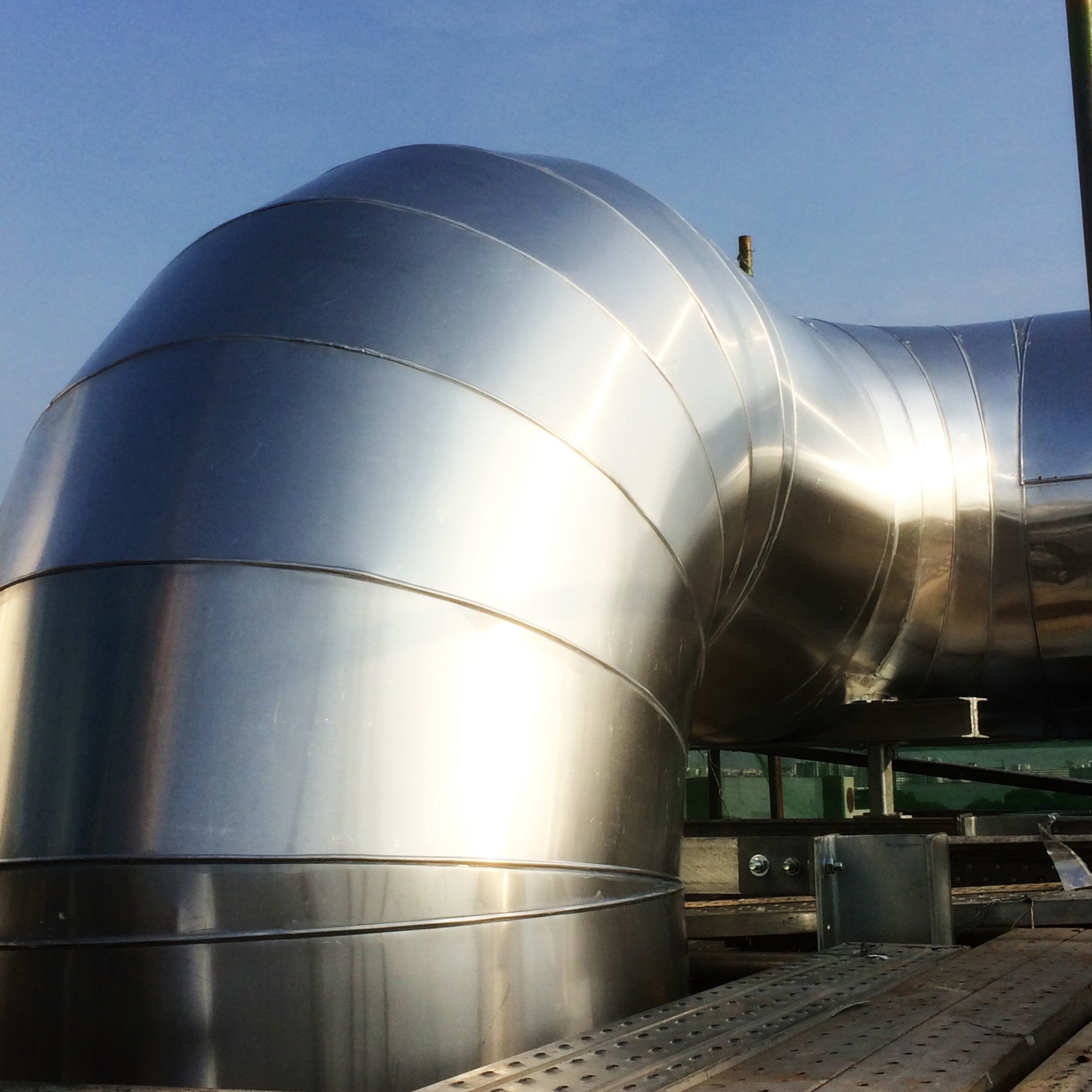

Norway's Renewable Energy Corporation (REC) integrated solar production facility is the largest plant construction project Goodever has taken in the recent years. The facility's total construction contracts amounted to over S$2.5 billion. Under the M&E phase, Techniques Air Conditioning & Engineering and Vinjoe Engineering awarded Goodever to provide specialised insulation works for all chilled water pipes, plant & pump rooms, and main pipe rack of the entire REC plant.

The REC facility has proven Goodever's ability to deliver huge project of its scale, where more than 25 tonnes of Aluminium sheets were supplied and used for Phenolic foam sectional insulation complete with Aluminium jacketing only. This opportunity allowed Goodever to develop its core capabilities to a higher level of competency.

We supplied K-flex insulation and PVC jacketing works for ASML machine hook up to IM Flash Singapore LLP (now wholly owned by Micron Technology as its fab 10N facility). K-flex insulation and PVC jacketing is one of our core capability, with the 200,000 square foot fab 10N being one of the large scale projects we delivered.

Smooth 90-degree elbow insulation and jacketing

K-flex insulation complete with PVC jacketing for clean air ducts

45-degree angle sections

45-degree angle sections

Elbow joint sections

In another IMFS site located at Senoko, we carried out K-flex insulation complete with Aluminium jacketing works for PCW systems.

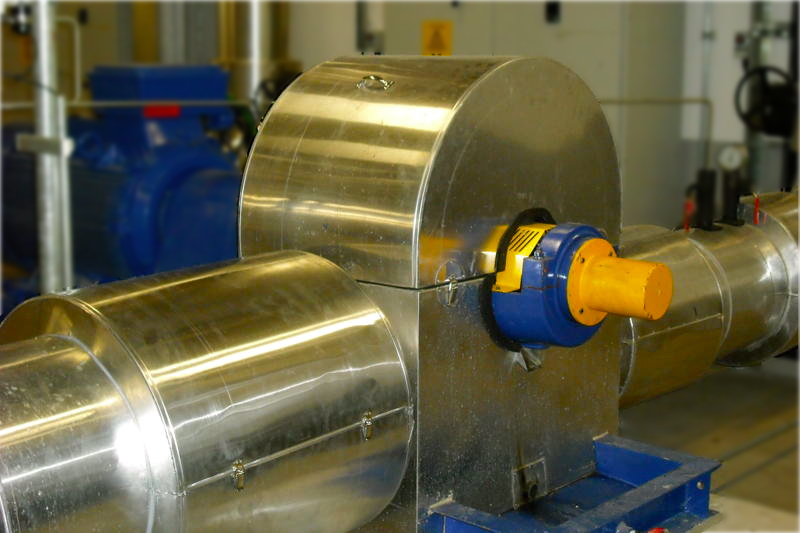

Pump insulation with K-flex complete with Aluminium jacketing

Y-strainer insulation with K-flex complete with Aluminium jacketing

Pipe elbow insulation with K-flex complete with Aluminium jacketing

Valve and elbow pipe section insulation with K-flex complete with Aluminium jacketing

Bypass elbow insulation with K-flex complete with Aluminium jacketing

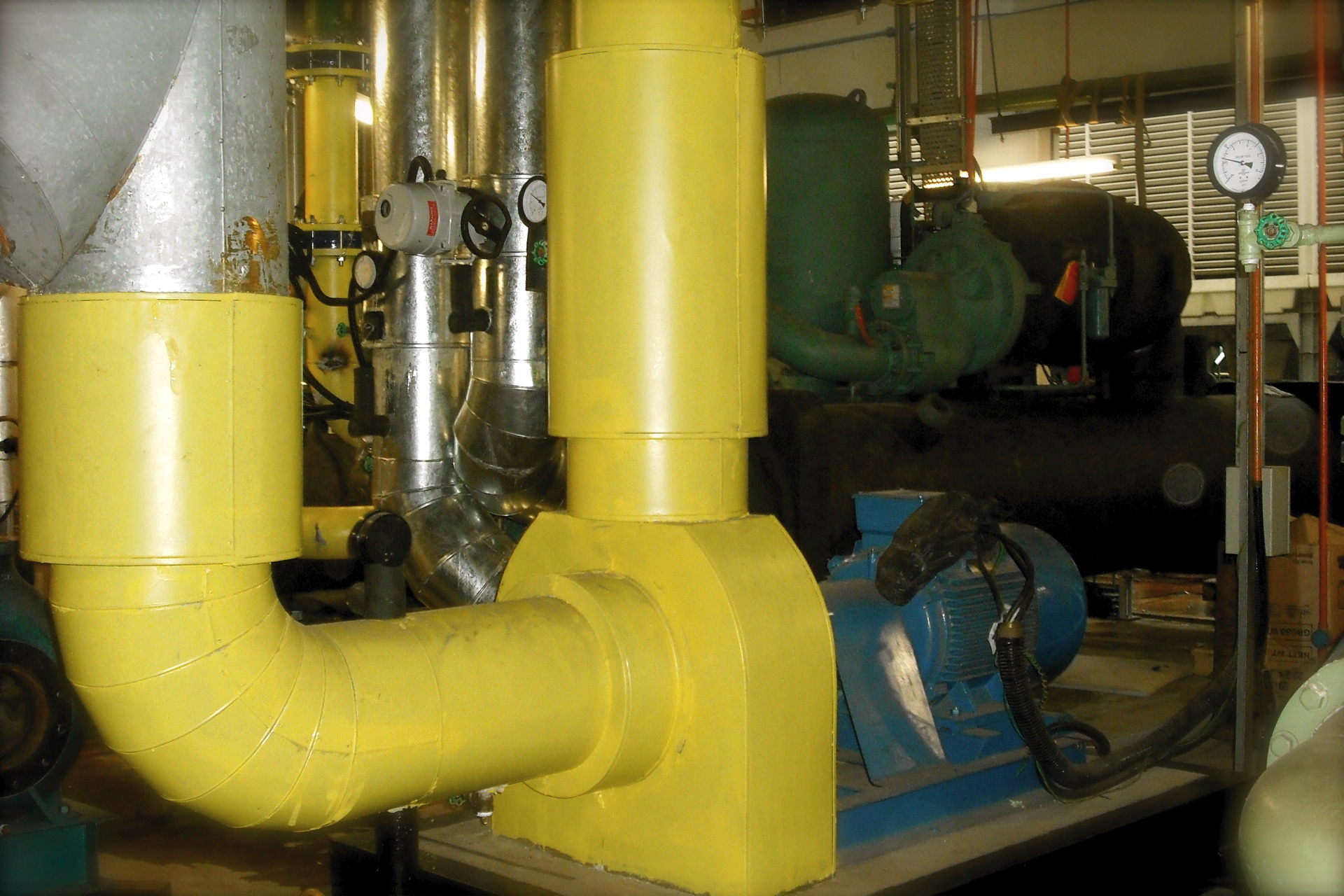

PU chemical with GI jacketing works were supplied to the expansion Biopolis project. At 37,000 square metres, the seven-storey complex was designed and constructed over 18 months at a cost of S$70 million.

Trane chiller insulation at DCS Biopolis 2000 R tonnes

The twenty years old suburban shopping mall cooling system was upgraded with new chillers. Through this project, we showcase our capability in carrying out jacketing and insulation work using K.flex and PU chemical. We supplied such works for 50 sets of chillers every year through our experience with Trane, Carrier and York chiller systems.

In the Tampines Mall upgrading project, we supplied jacketing and insulation work for the chiller system using K.flex and PU chemical.